Unveiling the Mystery of Aluminum Foil Prices

When sourcing aluminum foil for your business, you might notice a wide range of prices from different suppliers. This price discrepancy can be attributed to several factors, including the quality of raw materials, manufacturing processes, and supplier markups. Understanding these differences is crucial for making informed purchasing decisions.

Factors Contributing to Price Differences

Quality of Raw Materials: Higher-quality aluminum comes at a premium. Some suppliers use recycled aluminum, which is cheaper but may not have the same properties as virgin aluminum. The purity of the aluminum also affects its price and performance.

Manufacturing Processes: The precision and technology used in manufacturing can greatly impact costs. High-end machinery and advanced techniques result in more consistent and higher quality foil but increase production costs.

Supplier Markups: Different suppliers have varying business models. Some operate on high volumes with low margins, while others may provide additional services such as custom packaging, leading to higher prices.

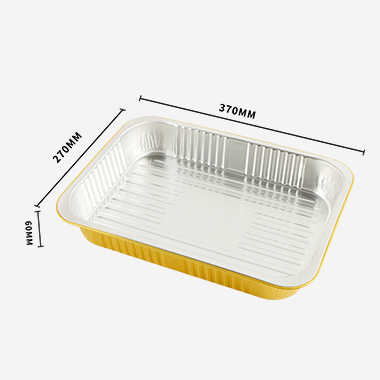

Thickness and Dimensions: The thickness of the foil and its dimensions (length and width) directly affect the material cost. More precise measurements and consistency in these dimensions often come at a higher price.

Verifying Aluminum Foil Specifications

To ensure you are getting what you pay for, it is essential to measure the aluminum foil you receive. This can be done by evaluating several key metrics: length, width, net weight of the roll, weight of the paper core, and thickness of the aluminum foil.

Measuring the Aluminum Foil

Length: Use a measuring tape to determine the total length of the foil. Lay the foil out flat on a clean surface and measure from one end to the other.

Width: Measure the width by laying the foil flat and measuring from one edge to the opposite edge with a ruler or measuring tape.

Net Weight: Weigh the entire roll of aluminum foil on a scale. To find the net weight, you will need to subtract the weight of the paper core.

Paper Core Weight: Weigh the paper core separately after unrolling the aluminum foil. This weight should be subtracted from the total roll weight to determine the net weight of the aluminum foil.

Thickness: Use a micrometer to measure the thickness of the foil. Take several measurements at different points to ensure consistency.

Analyzing the Measurements

Once you have all the measurements, compare them with the specifications provided by the supplier. This comparison will reveal any discrepancies. For example, if the thickness of the foil is less than what was advertised, you might be paying for less material than you thought. Similarly, discrepancies in length and width can also indicate you are receiving less product.

Conclusion

Understanding why aluminum foil prices vary and how to verify the specifications of the foil you receive can save your business money and ensure you are getting a quality product. By measuring the length, width, net weight, paper core weight, and thickness of your aluminum foil rolls, you can confidently assess whether the product meets your requirements and matches the supplier's claims.

Implementing these verification practices will not only help you get the best value for your money but also establish a more transparent and reliable relationship with your aluminum foil suppliers.